|

Getting your Trinity Audio player ready...

|

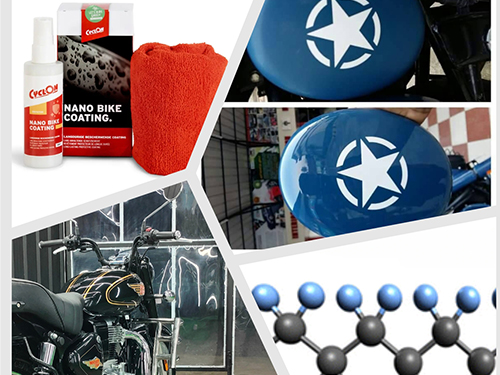

Long story short: Nano coating is a cutting-edge technology designed to take appearance of your bikes to the next level. With nano-coating, you can enjoy a low-maintenance, high-gloss finish that repels water, resists scratches, and keeps your bike looking as good as new, no matter where the road takes you. In this comprehensive guide, we delve into the world of nano bike coating, the differences between various bike coatings, and the pros and cons of nano bike coating.

Introduction

Nano coating technology is redefining the way we protect and maintain our bikes. Imagine a breakthrough that applies ultra-thin layers of nanoscale materials to surfaces, transforming their capabilities in remarkable ways.

Nanocoatings offer motorcycle enthusiasts an exciting solution to keeping their prized possessions in pristine condition. By creating water-repellent surfaces, these innovative coatings ensure that water and grime roll-off, safeguarding the bike’s frame and components from the harsh effects of the elements. Say goodbye to the days of stubborn dirt and moisture clinging to your ride—nano coatings are here to elevate your biking experience!

Key Takeaways

- Nano coating is a cutting-edge technology designed to take your bike’s appearance to the next level.

- Nano ceramic coatings protect against UV rays, scratches, and dirt, enhance gloss, ease cleaning, and boost resale value.

- Nano coatings for bikes can be costly, require expert application, and have limited protection. They need maintenance, may cause water spots, and risk non-genuine products.

- Nano-coated bikes require gentle cleaning, manual washes, regular checks, and reapplication. Proper storage and avoiding harsh conditions help maintain the coating’s effectiveness.

- Experts endorse nano coatings for their protection and longevity, while some users question their need for new bikes. Despite the cost, many view them as a worthwhile investment, stressing the importance of quality products.

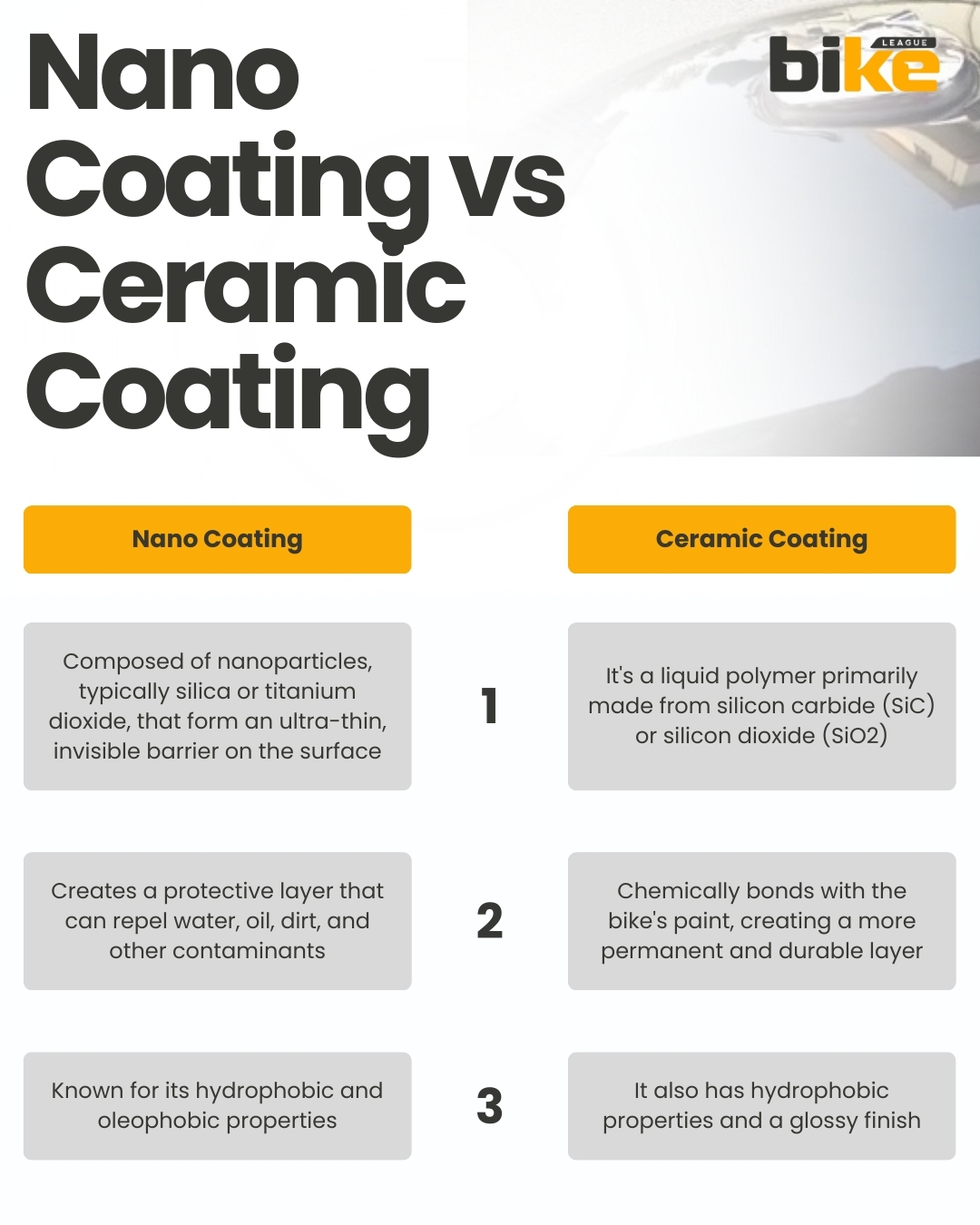

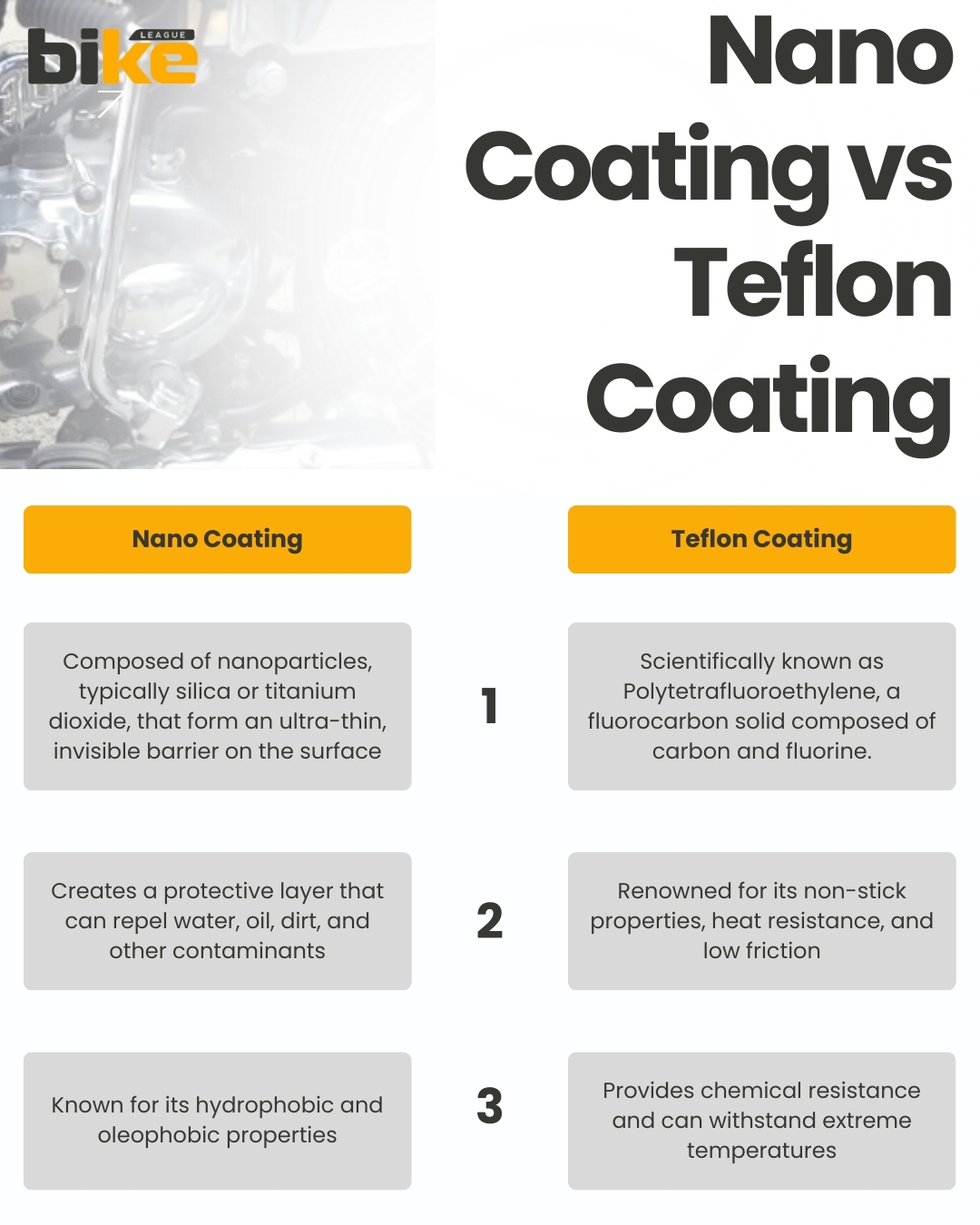

Difference between Nano, Ceramic, and Teflon coating for bikes in India

Nano Coating

- Composed of nanoparticles, typically silica or titanium dioxide, that form an ultra-thin, invisible barrier on the bike’s surface.

- Creates a protective layer that can repel water, oil, dirt, and other contaminants.

- Known for its hydrophobic and oleophobic properties.

Ceramic Coating

- Often referred to as nano-ceramic coating, it’s a liquid polymer primarily made from silicon carbide (SiC) or silicon dioxide (SiO2).

- Chemically bonds with the bike’s paint, creating a more permanent and durable layer.

- It also has hydrophobic properties and a glossy finish.

Teflon Coating

- Scientifically known as PTFE (Polytetrafluoroethylene), a fluorocarbon solid composed of carbon and fluorine.

- Renowned for its non-stick properties, heat resistance, and low friction.

- Provides chemical resistance and can withstand extreme temperatures.

Application Process

The application of nano coating to bikes involves several meticulous steps to ensure optimal protection and performance:

Step 1: Initial Cleaning

1. Thorough Wash:

- Use a high-quality bike shampoo to remove all dirt, grease, and residues.

- Clean all areas, including hard-to-reach spots, using bike-specific cleaners and brushes.

2. Degreasing:

- Apply a degreaser to remove grease or oil residues, especially around the chain and gear areas.

3. Drying:

- Dry the bike completely using a microfiber cloth to prevent water spots.

Step 2: Surface Preparation

1. Decontamination:

- Use a clay bar or decontamination product to remove stubborn contaminants like tar, bugs, or iron fallout.

2. Preparation Spray:

- Apply a preparation spray or carbon-safe degreaser to ensure the surface is free from oils or residues.

Step 3: Paint Correction (If Necessary)

If the bike’s paint has scratches, swirl marks, or oxidation, perform paint correction using a machine polisher and appropriate polishing compounds.

Step 4: Application of Nano Coating

1. Product Selection:

- Choose a high-quality nano coating product suitable for bikes, ensuring it’s safe for materials like carbon, aluminum, or titanium.

2. Application:

- Apply the coating using a microfiber cloth or an applicator sponge.

- Work in small sections to ensure even coverage across all bike parts, including the frame, rims, and handlebars.

Step 5: Curing

Depending on the product, the coating can cure for a specified time, varying from a few minutes to several hours.

Step 6: Final Buffing

After curing, gently buff the surface with a clean microfiber cloth to remove any excess coating and achieve a polished finish.

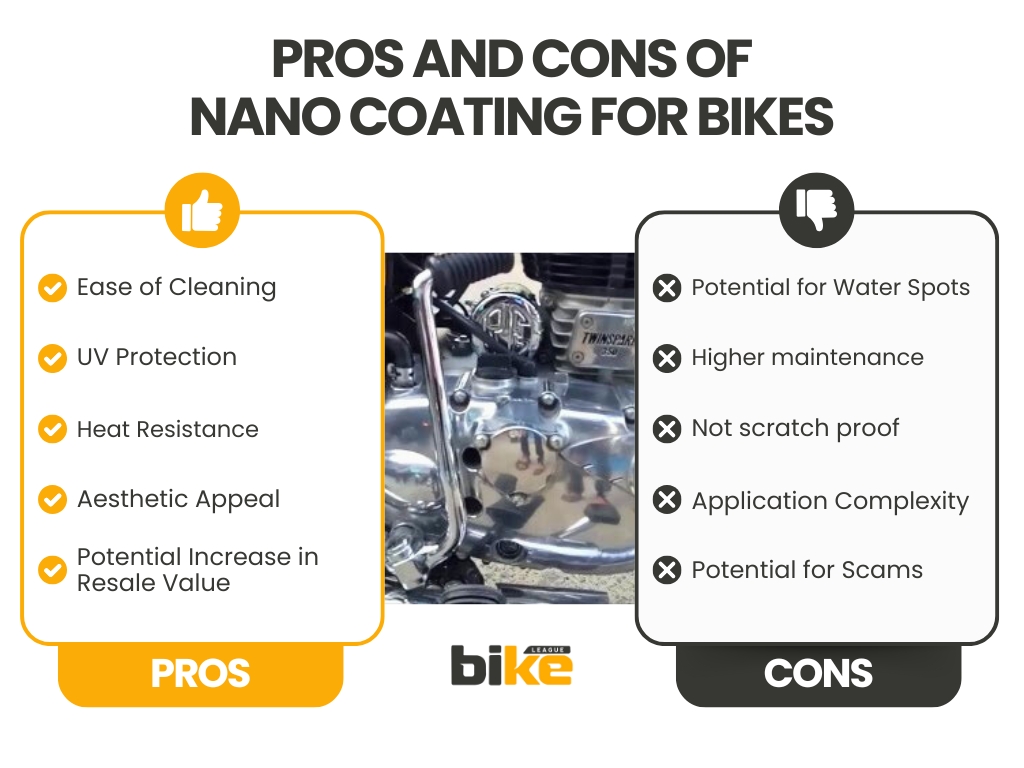

Pros of Nano Coating for Bikes in India

- Enhanced Protection: Nano ceramic coatings provide a robust protective layer that shields the bike’s paint from UV radiation, micro scratches, and environmental contaminants like dirt and salt.

- Durability: These coatings are known for their longevity, often lasting several years with proper maintenance.

- Aesthetic Appeal: Nanocoatings enhance the bike’s visual appeal by providing a glossy finish that highlights the bike’s features.

- Ease of Cleaning: Nano coatings’ hydrophobic properties make it easier to clean the bike, as water and dirt are less likely to adhere to the surface.

- Potential Increase in Resale Value: A well-maintained bike with a nanocoating can have a higher resale value due to its preserved appearance and protection against wear and tear.

- UV Protection: Nanocoatings offer excellent protection against UV rays, which is crucial in India due to the intense sunlight that can cause fading and discoloration of bike surfaces.

- Heat Resistance: Given the high temperatures in many parts of India, the heat resistance offered by nanocoatings is a significant benefit.

Cons of Nano Coating for Bikes in India

- High Initial Cost: Applying nanocoatings can be expensive, especially when done by professionals.

- Application Complexity: Proper application of nano coatings requires skill and precision. It is often recommended that professionals apply it to ensure even coverage and avoid potential health risks associated with improper handling of nanoparticles.

- Health and Safety Concerns: Nanocoatings, particularly those containing SiO2 particles, can pose health risks if inhaled or absorbed through the skin. Applying these coatings in a controlled environment with appropriate safety gear is crucial.

- Limited Protection Scope: While nano coatings offer excellent protection against certain elements, they do not make the bike scratch-proof or protect against all types of damage, such as fire burns or severe impacts.

- Potential for Scams: There is a risk of encountering non-genuine products or services, which may not provide the expected level of protection or durability. It is essential to choose reputable brands and service providers.

- Maintenance Requirements: Despite their protective qualities, nanocoatings require regular maintenance to ensure longevity. This includes proper washing techniques and using specific products to maintain the coating, which might not be feasible for all bike owners.

- Potential for Water Spots: Nanocoatings can make water spot formation easier. In areas with hard water, which is common in many parts of India, this can be a significant issue as the minerals in the water can leave marks on the coating.

Maintenance Requirements for Nano-Coated Bikes

Proper maintenance is crucial to ensure the longevity and effectiveness of nanocoatings on bikes. Here are the key maintenance requirements:

Gentle Cleaning

Use mild detergents to clean the bike, as harsh chemicals can degrade the coating over time. Employ soft cloths or sponges to avoid scratching the coating. Abrasive materials can damage the nanolayer, reducing its effectiveness.

Avoid Automatic Washes

Manual cleaning is preferred over automatic car washes, often using abrasive bristles that can harm the coating.

Regular Maintenance Checks

Perform annual maintenance checkups to inspect the bike for any signs of wear or damage to the coating.

Reapplication of Coating

Depending on usage and environmental exposure, periodic reapplication of the nanocoating may be necessary to maintain its protective properties.

Proper Storage

Store the bike in a dry and sheltered location to minimize exposure to harsh weather conditions, which can affect the longevity of the coating.

Avoid Harsh Conditions

While nano coatings provide excellent protection, minimizing exposure to extreme weather conditions can help prolong the coating’s effectiveness.

Recommended Brands and Products for Nano Coating

Several brands stand out in the Indian market for their quality and performance in nano coating applications for bikes:

- Labocosmetica

- Opti-Coat

- 3M

- Detailing Devils

- HYDRAX by ANT LAB

- Gyeon Quartz

- CarPro

Nano Coatings vs. Traditional Wax/Sealant

Nanocoating for bikes have several advantages over traditional wax and sealant applications:

Durability

Nanocoating offers long-lasting protection, often several years, compared to traditional wax or sealants that typically last from a few weeks to a few months.

Protection Level

NanocNanocoatingsngthen bikes by chemically bonding with them, offering superior protection against UV rays, dirt, and minor scratches.

Hydrophobic Properties

Nanocoatings have excellent hydrophobic and oleophobic properties, repelling water and oil-based substances. This helps keep the bike cleaner and reduces maintenance.

Aesthetic Enhancement

NanocNanocoatingside has a glossy finish that enhances the bike’s appearance, giving it a sleek and well-maintained look

Corrosion Resistance

Nano coatings have been shown to offer better performance in harsh environmental conditions, providing excellent corrosion resistance.

Maintenance Requirements

While nano coatings require less frequent maintenance than conventional wax or sealants, they require a more complex application process and often require seasonal installation.

Cost Considerations

Although nanocoatings have a higher initial cost, they can be more cost-effective due to their durability and reduced maintenance needs.

Expert Opinions and User Reviews

The general consensus among experts and users in India regarding nanocoatings for bikes is positive, with some considerations:

Effectiveness

Nano coatings are widely recognized for their superior protection and longevity compared to traditional methods.

User Skepticism

Some users express skepticism about the necessity of coatings for new bikes, suggesting that colors do not fade quickly and that such coatings might be more of a dealer tactic to increase sales.

Cost-Benefit Analysis

While the initial cost of nanocoatings is higher, many users and experts consider it a worthwhile investment due to the long-term benefits of enhanced protection and reduced maintenance.

Product Quality

Users emphasize the importance of choosing high-quality nano coating products, as cheaper options might not provide the expected benefits.

FAQ for Nano Coating for bikes in India

1. How long does nano coating last on a bike?

With proper care and maintenance, nano coatings last several years, typically up to 5 years or more.

2. How much does nano coating for bikes cost in India?

The cost typically ranges from ₹2,500 to ₹15,000 or more, depending on the type of coating, brand, and service provider.

3. Is nano coating better than Teflon coating for bikes?

Nanocoatings Are generally more durable. They offer more protection than Teflon coatings but are also more expensive.

4. Can I apply nano coating to my bike myself?

While DIY application is possible, professional application is recommended to ensure even coverage and adherence to safety protocols.

5. Does nano coating prevent scratches on bikes?

While nanocoatings give an extra layer of hardness, they don’t make the bike scratch-proof. It can, however, help minimize the impact of minor abrasions and swirl marks.

6. How does nano coating affect the bike’s appearance?

Nano coating enhances the bike’s appearance by providing a glossy finish and depth of color, making even older bikes look brand new.

7. Is nano coating safe for all types of bike surfaces?

Nano coating, including paint, plastic, and metal, is generally safe for most bike surfaces. However, it’s essential to use products specifically designed for bikes.

8. Can nano coating be applied to bike helmets and accessories?

Yes, nano coating can be applied to helmets and accessories, providing similar protective benefits to the bike.

9. Does nano coating make bike cleaning easier?

Yes, the hydrophobic properties of nano coating make cleaning easier as dirt and grime are less likely to adhere to the surface.

10. How does nano coating perform in Indian weather conditions?

Nano coating performs well in Indian weather conditions, offering protection against UV rays, acid rain, and humidity, which are common challenges in the Indian climate.

11. Is nano coating worth the investment for bikes in India?

While the initial cost is higher, many consider nano coating a worthwhile investment due to its long-term benefits, including enhanced protection, easier maintenance, and improved aesthetics.

12. Can nano coating be removed if needed?

It can, but typically requires professional intervention using specialized products and techniques.

13. How does nano coating affect the resale value of bikes?

Nano coating can increase the resale value of bikes by maintaining their appearance and protecting against wear and tear over time.

14. Are there any environmental concerns with using nano coating on bikes?

While nano coatings are generally considered safe, there are some concerns about the potential environmental impact of nanoparticles. It’s essential to follow proper application and disposal guidelines.

15. How often should nano coating be reapplied to a bike?

The frequency of reapplication depends on various factors, including usage and environmental exposure. Generally, reapplication may be necessary every few years to maintain optimal protection.

Here are some related articles from our team

- A comprehensive guide to choosing the right bike coating

- Bike ceramic coating : Unlock the Shine

- Diesel Wash For Bike: Is It Good or Bad

- Bike wash – Different types, procedures, precautions, FAQ

- Diesel bikes in India: Why are they absent on Indian roads ?

Conclusion

Nano coating technology for bikes in India offers several notable benefits, including enhanced protection, improved aesthetics, and easier maintenance. These advantages are precious given the country’s diverse environmental conditions. Nano coatings provide long-lasting defense against UV rays, water, and pollutants.

However, widespread adoption in a price-sensitive market can be challenging. High initial costs, the need for professional application, and ongoing maintenance can be hindrances. Additionally, consumers should be cautious of potentially misleading claims and the limitations of protection against physical damage.

Despite these challenges, the future of nano coating in India looks promising, thanks to the growing automotive industry, increasing consumer awareness, and technological advancements. As this technology evolves, bike maintenance and protection may undergo significant changes.

Bike owners should consider the pros and cons of nanocoating their budget and environmental factors while anticipating more options and affordable solutions.

If you have any questions or need more information about bike diesel wash benefits and limitations, email us at bikeleague2017@gmail.com or leave a comment below. We’re always here and happy to help! Similarly, don’t forget to check out Bikeleague India on our social media platforms to stay connected!